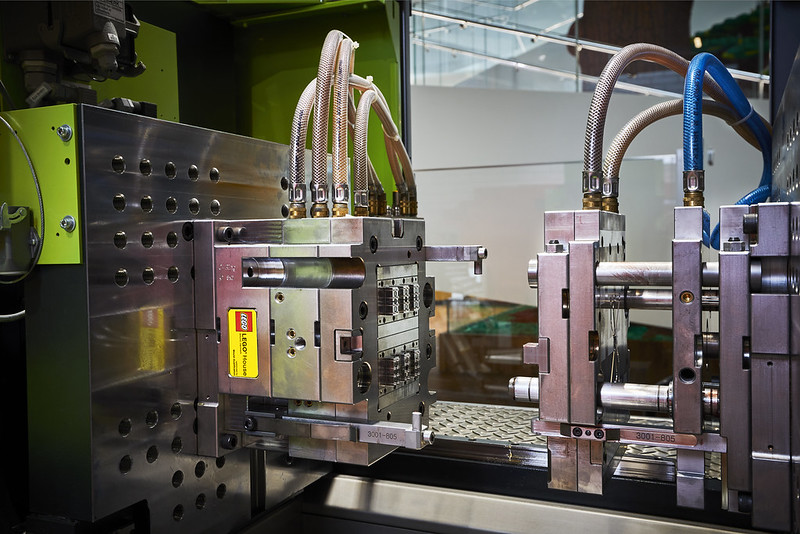

After the reveal of the latest LEGO® House Limited Edition set earlier today, part of the press pack for the new set included a brief history of injection moulding. This changed the face of the LEGO Group for good and helped the company become what it is today. That journey from wood to plastic began with a single moulding machine, which was ordered from the UK in the mid-1940s. Now almost 80 years on, moulding machines form an important part of LEGO facilities around the world including in Billund. I was lucky enough to see them in action when I visited the LEGO factory a few years ago and since then LEGO House has opened. The Billund-based attraction also features a working moulding machine, which churns out bricks for the LEGO House 6 brick polybag. Here’s a brief history of injection moulding and LEGO Brick Moulding Machines.

Injection moulding at the LEGO Group

The LEGO Group’s journey into plastic starts in the mid-1940s when company founder Ole Kirk Kristiansen places an order for a plastic injection moulding machine, thus kicking off the LEGO plastic era.

From wood to plastic

From the humble beginnings in 1932 until the late 1940s, the LEGO Group solely produces toys made of wood. As the years go by, production is steadily growing, and by the end of World War II, Ole Kirk is finding it increasingly difficult to source enough beechwood of the right quality to maintain production levels.

Ole Kirk has always had a curious mind and is constantly looking for new ideas and materials which he can use for his toy production. The lack of wood only gives him an even bigger incentive to satisfy his curiosity, and he turns his attention towards plastic. Invented in the middle of the 19th century, plastic has been on the market for quite a while, but in the mid-1940s, it has reached a level of quality which makes it suitable for producing toys.

The first machine

In June 1946, Ole Kirk – together with many other Danish toy manufacturers – attends a demonstration of a plastic injection moulding machine in Copenhagen. Ole Kirk is instantly convinced of the potential of both machine and material. Not even the price tag of 30,000 DKK, which by many, including Ole Kirk’s own son Godtfred, is considered to be a staggering amount of money to invest in this unproven technology, scares off Ole Kirk. He places an order for a British injection moulding machine soon after. The machine is produced by E. H. Windsor, London and it arrives in Billund late 1947.

The machine is operated by hand, and it takes up to four people to operate one single machine efficiently. The quality of the finished plastic product is very much based on the operator’s skills – and gut feeling – as there are no automatic controls of any kind.

Naturally, much experimenting is necessary in order to gain experience of the moulding process. However, slowly and steadily and with cellulose acetate as its raw material, the LEGO Group moves into the plastic age.

Betting on bricks

By 1949, the LEGO Group’s plastics department manufactures various kinds of toys. Among these are the company’s first plastic bricks, which are marketed under the name “Automatic Binding Bricks”. In 1958, the LEGO® brick as we know it today, with its interlocking stud and tube principle, is patented and introduced. Only two years later, the LEGO bricks are so successful that Godtfred Kirk Christiansen – 2nd generation LEGO owner – decides to put all eggs in one basket: He shuts down production of wooden toys alongside all other plastic toys and focuses 100% on the LEGO brick.

Ever-evolving technologies

Since the LEGO Group purchased its very first plastic injection moulding machine in 1946, the machines, as well as the moulds and the raw materials, have evolved dramatically. Up through the 1950s and 1960s, the company invests in several different types of machines in order to keep pace with rising production needs. As far back as 1950, it acquires a semi-automatic moulding machine with pneumatic injection built by Messrs Jørgen Bruun – a machine which continues in service until 1982.

In 1959, the first fully automatic moulding machine is purchased, and soon efficiency increases as one LEGO employee now operate two machines.

By 1972, the moulding facility in Billund has been expanded several times, and 172 moulding machines are now being operated here. By the early 1990s, the LEGO Group is producing LEGO bricks in five moulding facilities around the globe, and the total number of moulding machines has increased to 1,000.

Billions of bricks

In 1997, the first of a total order of 75 new types of moulding machines are delivered in Billund. Along with existing machines as well as many new ones added during the years, these machines have since been used for production of billions of LEGO bricks.

In today’s LEGO moulding facilities, it takes only one LEGO employee to operate 32 machines in a standard setup, and at the moulding facility in Billund, the machines produce a total of 1,360 LEGO elements each second.

The type of moulding machine portrayed in this LEGO House Exclusive building set is in fact a detailed replica of one of the types of moulding machines currently operating in the Billund moulding factory.

- The moulding process is the corner stone of manufacturing LEGO® bricks

- The LEGO Group purchases the first plastic injection moulding machine in 1946

- The first injection moulding machines are operated manually

- In 1950, the first semi-automatic injection moulding machine is purchased

- The first LEGO factory dedicated only to plastic injection moulding is built in 1953 as an extension to the existing woodworking factory on Systemvej in Billund

- In 1959, the first fully automatic moulding machine is installed in Billund

- Today the LEGO Group has moulding facilities in Billund (Denmark), Nyíregyháza (Hungary), Monterrey (Mexico), and Jiaxing (China)

- At the moulding facility in Billund, the machines are producing a total of 4.9 million LEGO bricks per hour

A real-life moulding machine in LEGO House

In LEGO House guest can experience a real LEGO injection moulding machine up close. The green moulding machine is identical to the moulding machines found at the LEGO production sites in Denmark, Hungary, Mexico and China. The only difference is that the specially designed mould in LEGO House only contains 4 LEGO bricks and that the speed has been dialled down significantly to prevent an overproduction.

Fun-fact: To keep decommissioned moulds from falling into the wrong hands, Godtfred Kirk Christiansen initiates that moulds should be cast into the concrete foundation of new factories. Around 1980, the LEGO® Group revises its policy and instead sends the moulds to Danish steelworks for destruction.

915,103,765 combinations

In 2004 Danish mathematics professor, Søren Ejlers calculates that the number of unique ways you can combine six 2×4 LEGO bricks of the same colour is an incredible 915,103,765.

This astonishing fact demonstrates what we mean when we talk about the endless possibilities of the LEGO brick.

As a memento of a visit to LEGO House each and every guest is assigned one of these unique combinations. And of course, the guests get to pick up 6 steaming fresh LEGO bricks directly from the moulding machine.

The evolution of LEGO ® bricks

In the History Collection of LEGO House visitors can embrace the history of the brand. Not least the story behind the LEGO® bricks is fascinating: From the late 1940’s more and more plastic toys are produced at the factory in Billund. Among these are the boxes of Automatic Binding Bricks – small plastic bricks in different sizes made for stacking. The bricks themselves strongly resemble today’s basic LEGO ® bricks: the dimensions are identical and the studs on top are virtually the same, but the inside is hollow.

Clutch power

Complaints are received from foreign markets about insufficient stability in the building experience. Godtfred Kirk Christiansen has witnessed the problem first-hand while watching his own children play with LEGO® bricks. He assembles a team to solve the challenge and after many nights of hard work, they come up with an interlocking principle by adding inner tubes compatible with the studs on top of a LEGO brick.

3rd September 2023

Hello Adam,

In my research of vintage Lego bricks I have found ones with mould injection points on the side and in the bottom corner. Sometimes in the late 70s or early 80s Lego started injecting plastic into moulds on the top of one stud on plates and bricks. I have searched far and wide but failed to find any information when exactly this transition occurred.

As you have seen these plastic moulding machines, maybe you have been told this? I am very curious as I like my vintage sets to be accurate up to the point of correct bricks from correct time.

3rd September 2023

Hi George, although I have seen both the original and the current machines, no information was given on the exact moments things were changed. I would suggest maybe getting in touch with the LEGO Ideas House team who detail and collate the history of the LEGO Group. They may be of more help than I can be.